Pit type aging furnace

- Overview

- Parameter

- Inquiry

- Related Products

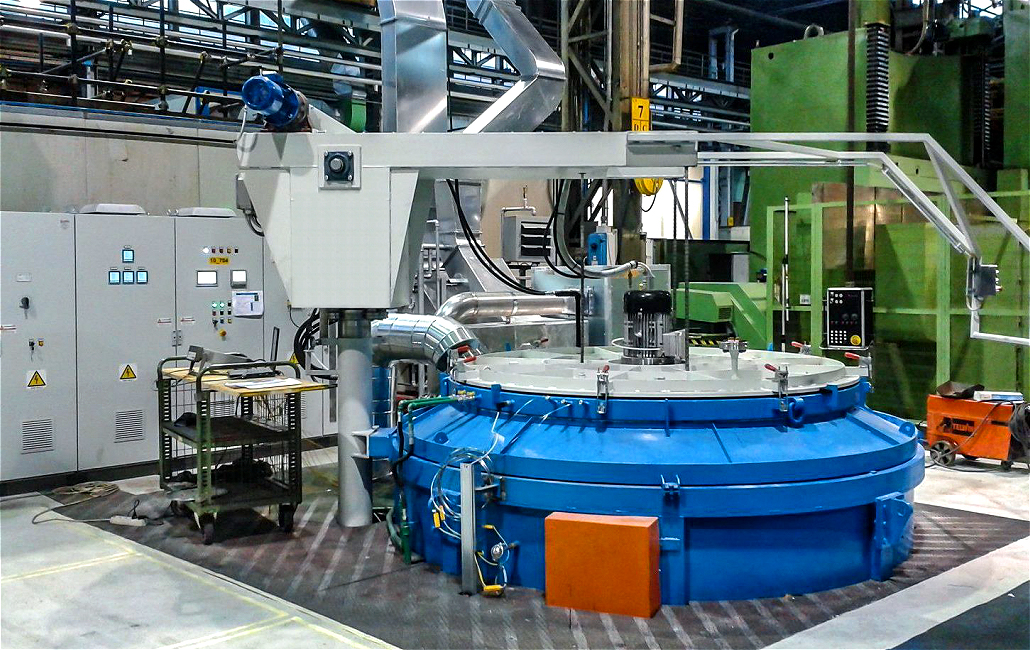

The outer cover of the pit-type aging furnace is composed of a steel plate shell, a furnace lining and a furnace top beam. The design of the inner tube and the convection tube ensures that the workpiece is evenly heated during the heating process. The inner tube has good sealing performance and strong heat resistance and oxidation resistance. The convection tube provides a convection channel with a controlled atmosphere to ensure that the hot air flow is evenly distributed in the furnace.

The furnace cover and furnace body are made of heat-resistant fiber cotton and other insulation materials, which have good insulation performance and can reduce energy consumption and production costs. The furnace lining is built with ultra-lightweight energy-saving micro-bead refractory insulation bricks, which further improves the energy-saving effect.

The pit-type aging furnace does not produce harmful substances during the heating process and is environmentally friendly.

It is widely used in mechanical processing, metallurgy, automobile manufacturing and other fields, mainly used for aging treatment of metal materials such as alloy steel, high-speed steel, high-manganese steel, etc. In addition, it can also be used for heat treatment and surface modification of other materials.

To ensure safe operation, the furnace cover adopts a manual or electric lifting mechanism, and a limit switch is installed near the lifting mechanism to cut off the power supply when the furnace cover is opened to prevent accidents.

| Item | Parameter |

|---|---|

| Diameter Range | 80mm~600mm |

| Pipe Length | 1-10m |

| Material | Silicone cloth / non-woven / canvas |

| Fabric Thickness | 0.2-0.3mm |

| Fabric Width | 110mm |

| Metal Strip Width | 11mm |

| Metal Strip Thickness | 0.4-0.5mm |

| Motor Power | 2.2KW |

| Forming Speed | 1-15 m/min |

| Weight | 500KG |

| Dimension | 2200 X650 X1200mm |