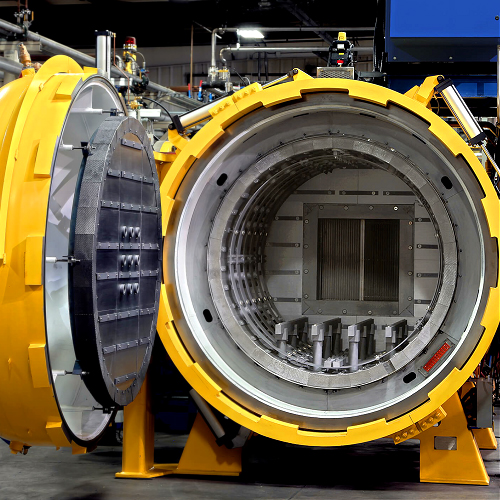

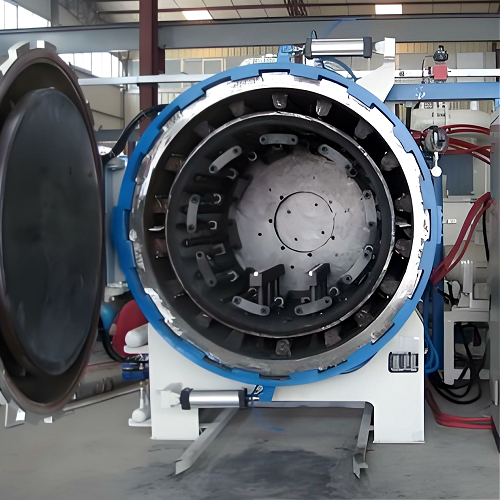

Vacuum water quenching furnace

- Overview

- Parameter

- Inquiry

- Related Products

By spraying cooling water at high speed in a vacuum environment, the material temperature is quickly reduced, thereby effectively improving the hardness and strength of the material. This is very important for the preparation of some high-strength materials, especially in aerospace and automobile manufacturing.

It can improve the surface properties of materials and increase their wear resistance and corrosion resistance. This has a significant effect on workpieces that require high wear resistance and high corrosion resistance, such as tools and molds.

Compared with traditional heating and cooling methods, vacuum water quenching furnace can greatly reduce heating and cooling time by quickly lowering the material temperature, thereby significantly reducing energy and material consumption.

The temperature can be evenly controlled during use because advanced processing technology and design are used to ensure the stability of temperature control.

The advanced mechanical system is adopted, which has stable operation and low failure rate, ensuring the long-term stable operation of the equipment.

It adopts intelligent PID control, is easy to operate, supports a variety of quenching process options, and is suitable for use in various scenarios.

Heat treatment in a vacuum environment can effectively remove grease and impurities on the surface of the workpiece, improve the quality of the workpiece, and reduce pollution to the environment.

| Model | Working size (mm) |

Max.Temp (°C) |

Capacity (kgs) |

Temperature Uniformity (°C) |

Power (kw) |

Ultimate Vacuum |

|---|---|---|---|---|---|---|

| DM-QCL-334 | 300*300*450 | 1320 | 100 | +5 | 50 | 6*10-3Pa |

| DM-QCL-446 | 400*400*600 | 1320 | 200 | +5 | 80 | 6*10-3Pa |

| DM-QCL-557 | 500*500*700 | 1320 | 300 | +5 | 120 | 6*10-3Pa |

| DM-QCL-669 | 600*600*900 | 1320 | 500 | +5 | 150 | 6*10-3Pa |