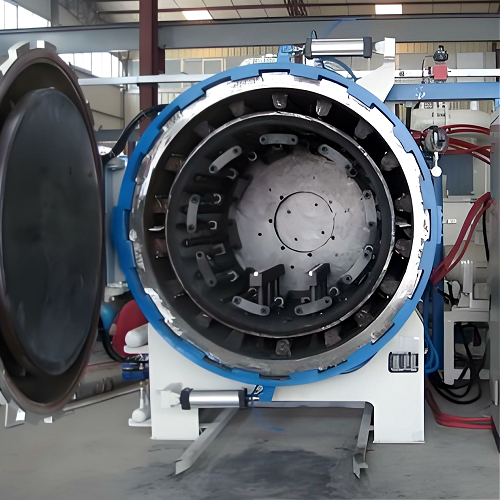

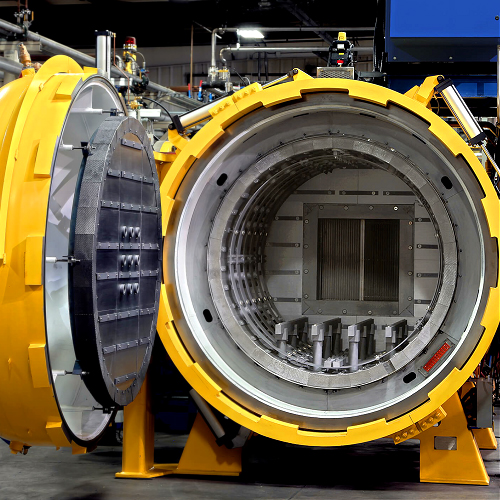

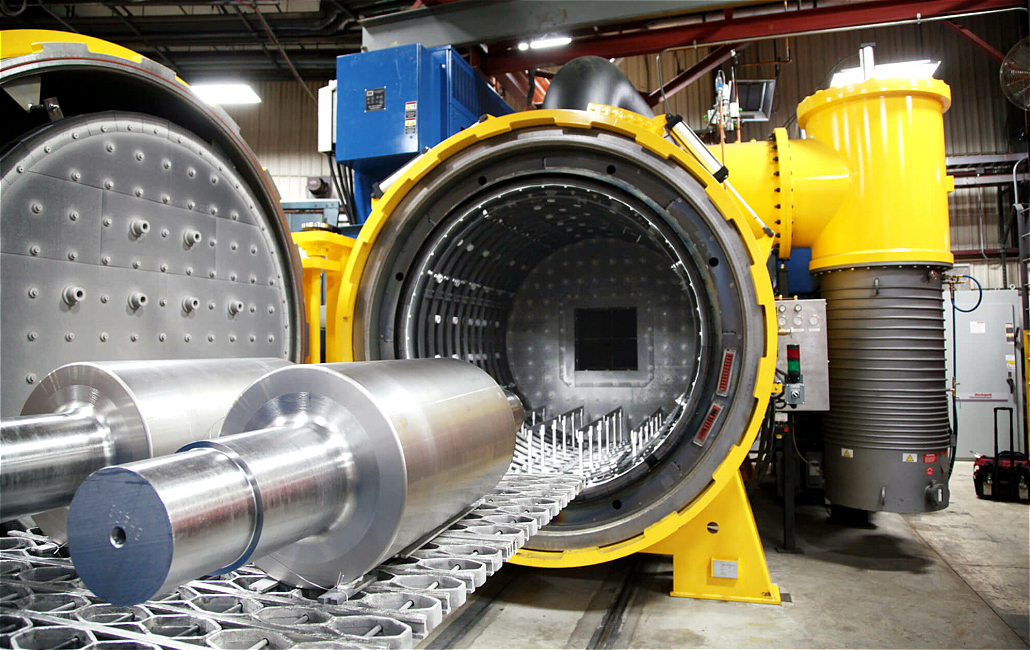

Vacuum nitriding furnace

- Overview

- Parameter

- Inquiry

- Related Products

It can provide a high temperature environment, usually reaching a temperature of more than 2000℃, which is suitable for the sintering preparation process of high temperature alloys, cemented carbides and other materials. The high temperature environment is conducive to the sintering, crystallization and phase change of materials, and improves the density, hardness and wear resistance of materials.

It can provide an oxygen-free or low-oxygen sintering environment to prevent the material from being oxidized and damaged in oxygen. Materials sintered in an oxygen-free environment usually have higher purity and stability, and are suitable for preparing high-precision, high-performance materials.

By optimizing the heating system and control technology, the vacuum sintering furnace can achieve uniform heating of the material, ensure that the entire workpiece is evenly heated at high temperature, avoid thermal stress concentration and deformation, and improve the forming accuracy and mechanical properties of the material.

With the characteristics of high vacuum, it can effectively remove gas and impurities on the surface and inside of the workpiece, and improve the purity and density of the material. High vacuum is also conducive to reducing the impact of gas and impurities on material properties and improving the stability and reliability of the material.

With a closed-loop heating system and advanced thermal insulation structure, the vacuum sintering furnace can effectively control energy consumption and heat loss in a high-temperature environment, and has high energy utilization efficiency and energy-saving and emission reduction effects. At the same time, the oxygen-free environment and high vacuum degree are also conducive to reducing waste gas emissions and environmental pollution during the material preparation process.

The use of resistance heating and intelligent temperature controller has high temperature control accuracy and can meet the requirements of different materials. Continuous temperature measurement through optical fiber infrared radiation thermometer and armored thermocouple ensures the accuracy and stability of temperature.

It has the functions of flexible vacuuming, vacuum sintering, micro-positive pressure sintering, partial pressure sintering, micro-positive pressure degreasing, etc. It is easy to operate and has high reliability. In addition, it also has functions such as over-temperature and over-pressure fault alarm, mechanical automatic pressure protection, remote operation, remote fault diagnosis and software upgrade to ensure the safety and intelligence of the equipment.

| Model | Working size (mm) |

Uitimate pressure (pa) |

Pressure risingratel (pa/h) |

Loadingcapacity (kg) |

Cooling gas pressure (bar) |

|---|---|---|---|---|---|

| CDO-VQ-20 | 200*200*200 | 4*10^-1~6.7*10^-3 | 0.67 | 50 | 6/10/15/20 |

| CDO-VQ-30 | 300*300*500 | 4*10^-1~6.7*10^-3 | 0.67 | 100 | 6/10/15/20 |

| CDO-VQ-40 | 400*400*600 | 4*10^-1~6.7*10^-3 | 0.67 | 200 | 6/10/15/20 |

| CDO-VQ-50 | 500*500*700 | 4*10^-1~6.7*10^-3 | 0.67 | 300 | 6/10/15/20 |

| CDO-VQ-60 | 600*600*900 | 4*10^-1~6.7*10^-3 | 0.67 | 500 | 6/10/15/20 |

| CDO-VQ-70 | 700*700*1000 | 4*10^-1~6.7*10^-3 | 0.67 | 700 | 6/10/15/20 |

| CDO-VQ-80 | 800*800*1200 | 4*10^-1~6.7*10^-3 | 0.67 | 1000 | 6/10/15/20 |

| CDO-VQ-v50 | Ф500*700(vertical) | 4*10^-1~6.7*10^-3 | 0.67 | 300 | 6/10/15/20 |

| CDO-VQ-v70 | Ф700*900(vertical) | 4*10^-1~6.7*10^-3 | 0.67 | 500 | 6/10/15/20 |

| CDO-VQ-v100 | Ф1000*1000(vertical) | 4*10^-1~6.7*10^-3 | 0.67 | 800 | 6/10/15/20 |

| CDO-VQ-v120 | Ф1200*1000(vertical) | 4*10^-1~6.7*10^-3 | 0.67 | 1000 | 6/10/15/20 |