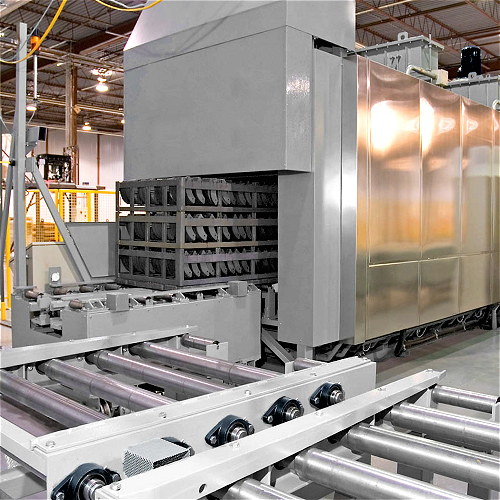

Box type multi-purpose nitriding furnace

- Overview

- Parameter

- Inquiry

- Related Products

The advanced carburizing and nitriding process makes superior effect , and achieves high carburizing and nitriding depth and uniformity in a short time, which significantly improves the surface hardness, wear resistance, corrosion resistance and fatigue life of metal materials.

The box-type multi-purpose nitriding furnace is easy to operate, of high control precision, and can be automatically controlled through the operation interface such as touch screen, which reduces the tedious degree of manual operation and the labor intensity of the operator.

Adopting advanced heating methods and high temperature insulation materials, the equipment runs stably with high heating efficiency and energy saving performance.

It can handle various metal materials, including carbon steel, alloy steel, stainless steel, cast iron, etc., and can be flexibly processed according to different process requirements.

During the treatment process, the equipment is fire-free, oil-free, smoke-free, environmentally friendly, and has safety performance. Unmanned operation makes the system automatically shut down in the case of fire, explosion, earthquake, etc., to ensure safety.

The processing time of the workpiece is little and the deformation amount is small, while can significantly improve the fatigue strength, wear resistance and corrosion resistance of the workpiece.

The operation is simple and convenient. Advanced hydrogen probe and program control instrument can be used to control the nitrogen potential in the furnace.

| Model | Heating power (kw) |

working temperature (°C) |

working size (mm) |

Temp uniormity (±°C) |

Loading capacity (kg) |

|---|---|---|---|---|---|

| CNC-400 | 36 | 500~650 | 900*600*600 | ≤5 | 400 |

| CNC-600 | 55 | 500~651 | 1200*600*600 | ≤5 | 600 |

| CNC-1000 | 80 | 500~652 | 1200*760*800 | ≤5 | 1000 |

| CNC-2500 | 180 | 500~653 | 1800*900*900 | ≤5 | 2500 |