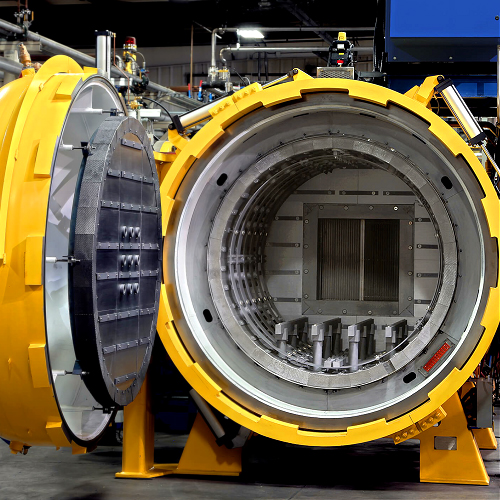

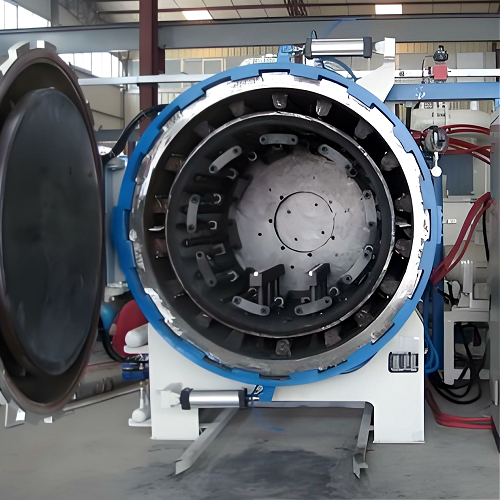

Vacuum brazing furnace

- Overview

- Parameter

- Inquiry

- Related Products

Working in a high temperature and high vacuum environment can effectively avoid oxidation and gas pollution, thereby ensuring the quality of the weld and reducing problems such as impurities and cracks in the weld. 1. The welding process in this environment can ensure the strength and airtightness of the welded joint, and improve the reliability and service life of the product.

No flux is used in the vacuum brazing process, which significantly improves the corrosion resistance of the product, avoids various pollutions, and improves safe production conditions. In addition, the vacuum brazing furnace does not produce harmful gases and smoke during the welding process, which meets environmental protection requirements.

No complicated flux cleaning process is required, which saves a lot of expensive metal flux and reduces production costs. At the same time, the energy consumption of the vacuum brazing furnace is low, which further reduces operating costs.

It is suitable for a variety of materials, including aluminum, aluminum alloy, copper, copper alloy, stainless steel, alloy steel, low carbon steel, titanium, nickel, etc. This wide applicability makes vacuum brazing furnace widely used in many industries.

Through precise temperature control and vacuum environment, the accuracy of welding joint position and size is guaranteed, and the quality and reliability of the product are improved. In addition, the vacuum environment can effectively remove gas and impurities, and reduce pores and inclusions during welding.

It can be operated and controlled through automation technology to improve production efficiency and product quality, reduce manual intervention and human errors, and reduce production costs.

| Type | Size (mm) |

Loading Capacity (kg) |

Heating Material |

Heating Power (kw) |

Maximum Temperature (°C) |

Temperature Uniformity (±°C) |

Ultimate Vacuum (Pa) |

|---|---|---|---|---|---|---|---|

| VTHB-335 | 300*300*500 | 100 | Molybdenu m/Graphite |

60 | 1300°C | 5°C | 6*10-4 |

| VTHB-446 | 400*400*600 | 200 | Molybdenu m/Graphite |

80 | 1300°C | 5°C | 6*10-4 |

| VTHB-557 | 500*500*700 | 300 | Molybdenu m/Graphite |

100 | 1300°C | 5°C | 6*10-4 |

| VTHB-669 | 600*600*900 | 500 | Molybdenu m/Graphite |

150 | 1300°C | 5°C | 6*10-4 |

| VTHB-8812 | 800*800*1200 | 800 | Molybdenu m/Graphite |

210 | 1300°C | 5°C | 6*10-4 |

| VTHB-1115 | 1000*1000*1500 | 1000 | Molybdenu m/Graphite |

350 | 1300°C | 5°C | 6*10-4 |

| VTHB-9918 | 900*900*1800 | 1200 | Molybdenu m/Graphite |

360 | 1300°C | 5°C | 6*10-4 |