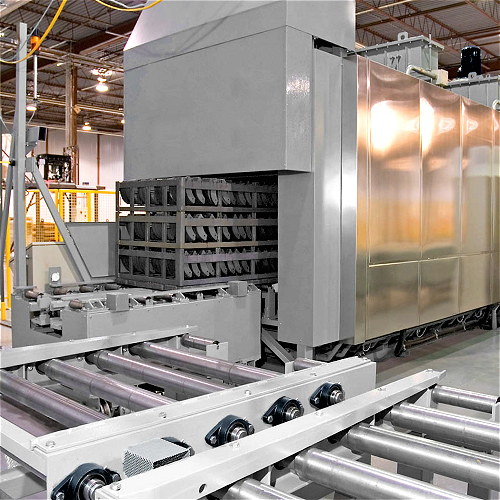

Box-type carbonitriding multi-purpose quenching furnace

- Overview

- Parameter

- Inquiry

- Related Products

Adopting advanced modern carburizing and nitriding processes, the equipment can achieve high carburizing and nitriding depth and uniformity in a short period of time, then significantly improves the surface hardness, wear resistance, corrosion resistance and fatigue life of metal materials.

The box-type multi-purpose nitriding furnace is easy to operate, of high control precision, and can be automatically controlled through the operation interface such as touch screen, which reduces the tedious degree of manual operation and the labor intensity of the operator.

Adopting advanced heating methods and high temperature insulation materials, the equipment runs stably with high heating efficiency and energy saving performance.

It can handle various metal materials, including carbon steel, alloy steel, stainless steel, cast iron, etc.. Meanwhile it can carry out a variety of heat treatment operations according to different process requirements, with strong applicability and flexibility.

The heat treatment quality of the equipment is stable. Full computer control and automatic operation makes fewer operators and good working environment. The multi-purpose furnace is a gap type production, the same as the well furnace. According to the requirements of heat treatment technology, different products can be produced separately. It can be mass-produced and also medium-mass produced. The production capacity is higher than the well furnace and lower than the continuous furnace.

| Model | Power (kw) |

Working size (mm) |

Loading capacity (kg) |

Body size (mm) |

quenching heating power (kw) |

working temperature

(°C) |

Quenching working temp.

(°C) |

|---|---|---|---|---|---|---|---|

| SQC-650 | 90 | W650*H650*L1100 | 650 | W2400*H4000*L4400 | 30 | 800~950 | 60~130 |

| SQC-1200 | 142 | W700*H850*L1300 | 1200 | W2600*H4600*L4700 | 48 | 800~950 | 60~130 |

| SQC-1500 | 180 | W900*H900*L1500 | 1500 | W2800*H5000*L5300 | 64 | 800~950 | 60~130 |

| SQC-3000 | 270 | W1400*H900*L1800 | 3000 | W4700*H5700*L7000 | 72 | 800~950 | 60~130 |