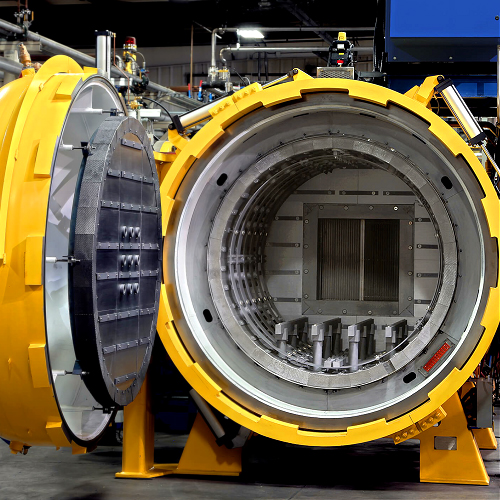

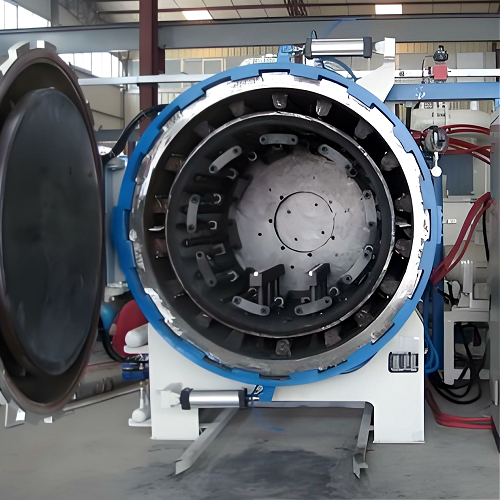

Vacuum oil quenching furnace

- Overview

- Parameter

- Inquiry

- Related Products

The high-efficiency constant temperature system can accurately control the temperature in the furnace within the set range, while achieving uniform temperature and ensuring uniform surface temperature of the workpiece, which is beneficial to improving the surface hardness and strength of the workpiece.

In a high temperature environment, the hydrogen released from the oil will form bubbles on the surface of the workpiece, forming pressure and flow, which is conducive to the invasion of oil and the improvement of quenching effect. In addition, the heating amount of the quenching oil can be automatically controlled, which can increase the quenching speed and speed up the heat treatment process while ensuring the quenching quality.

It is suitable for high temperature treatment of various materials, such as normalizing treatment of fine parts, surface nitriding treatment, stainless steel annealing and refining treatment of conventional rolling bearings.

Through vacuum oil quenching, a bright workpiece can be obtained with no oxidation or decarburization on the surface, and with good structure and performance.

The vacuum oil quenching furnace has a faster cooling speed, which can improve production efficiency and reduce production costs.

The quenching medium is a green, high-purity inert gas, such as helium or nitrogen, which does not pollute the workpiece surface, has high cleanliness, and is friendly to the workshop environment.

| Model | Effective area size (mm) |

Capacity (kg) |

Power (kw) |

Max.Temp (°C) |

Temperature Uniformity (±°C) |

Vacuum (Pa) |

Pressure rise rate (Pa/h) |

Air cooling pressure (bar) |

|---|---|---|---|---|---|---|---|---|

| DM-QCL-555 | 500*500*500 | 100 | 80 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-644 | 600*400*400 | 20 | 100 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-755 | 700*500*500 | 300 | 120 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-966 | 900*600*600 | 500 | 150 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-8812 | 800*800*1200 | 800 | 240 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-9916 | 900*900*1600 | 2000 | 550 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |

| DM-QCL-2010 | 2000*1000*1000 | 1000 | 850 | 1350 | 5 | 6*10-3 | 0.67 | 6/10 |