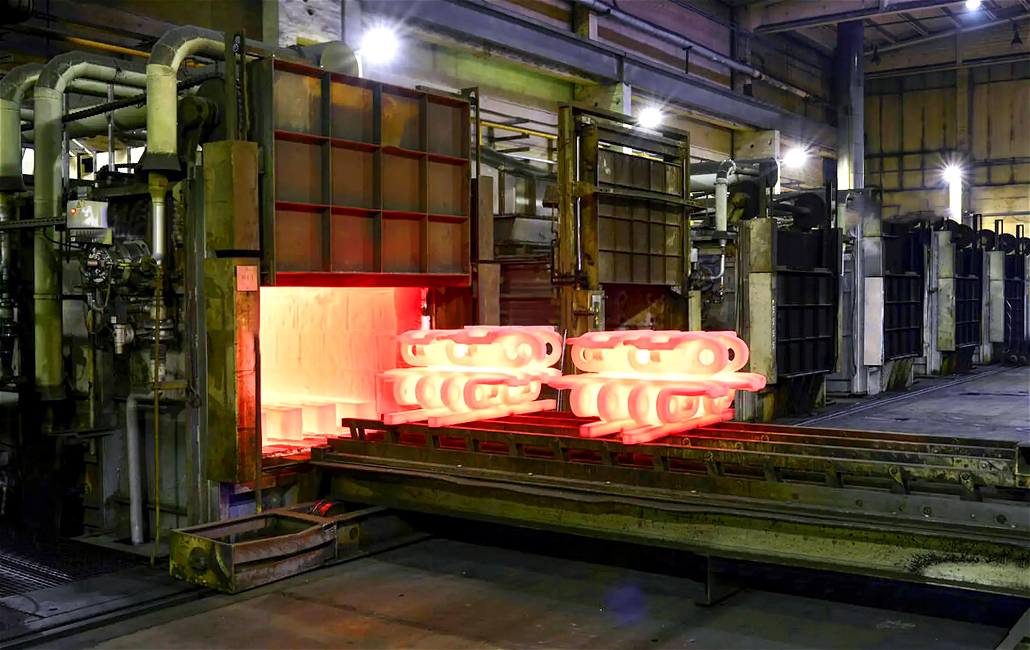

Box annealing furnace

- Overview

- Parameter

- Inquiry

- Related Products

The electric heating method is adopted, the heat energy loss is small, the temperature can be quickly raised, the production cycle can be shortened, and the production efficiency can be improved. At the same time, the equipment has the characteristics of rapid cooling, which can save more energy.

The heat treatment process does not produce pollutants such as waste gas, waste water, and waste slag, and will not affect the environment. In addition, the equipment adopts high-temperature protection measures, which can effectively prevent the occurrence of safety accidents such as furnace explosion and leakage.

The main components are made of high-temperature alloy materials, which have good oxidation resistance, corrosion resistance, high temperature resistance, etc., have a long service life, and can operate stably for many years under high temperature conditions.

It is suitable for annealing, aging, quenching, tempering and other heat treatment processes of various materials, and can meet the production needs of different fields. In addition, the equipment is simple to operate and easy to maintain, which can improve production efficiency and economic benefits.

The box-type structure ensures uniform temperature distribution in the furnace and improves the processing quality.

The electric furnace uses an intelligent digital display PID to automatically control the furnace temperature, with high precision, and can adjust the atmosphere in the furnace as needed to meet different process requirements.

It is equipped with a chain protection device to prevent failures and accidents caused by misoperation. In addition, the equipment has complete safety protection measures to ensure the safety of operators.

| Model | Rated power (kw) |

Rated Voltage (v) |

Rated Temperature (°C) |

Phases |

Effective working Size (mm) |

Effective working Size (mm) |

|---|---|---|---|---|---|---|

| RX3-20-12 | 20 | 380 | 1200 | 3 | 1100*550*450 | 650*300*250 |

| RX3-45-12 | 45 | 380 | 1200 | 3 | 1500*800*600 | 950*450*350 |

| RX3-65-12 | 65 | 380 | 1200 | 3 | 2100*850*750 | 1200*600*400 |

| RX3-90-12 | 90 | 380 | 1200 | 3 | 2100*1050*750 | 1500*750*450 |

| RX3-115-12 | 115 | 380 | 1200 | 3 | 2400*1500*700 | 1800*900*550 |

| RX3-145-12 | 145 | 380 | 1200 | 3 | 3000*1350*950 | 2100*1050*750 |