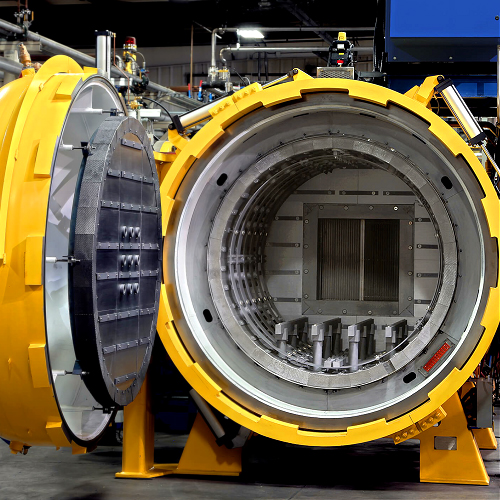

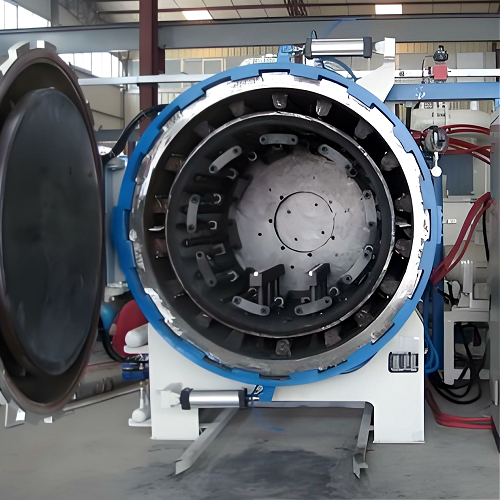

Vacuum carburizing furnace

- Overview

- Parameter

- Inquiry

- Related Products

Carburizing can be performed in a vacuum environment. Since there is no gas interaction, the carbon can reach the surface of the steel faster, thus achieving better carburizing layer uniformity and surface quality.

During high-temperature carburizing, since there is no heat loss from gas reaction, the carburizing time can be greatly shortened, thereby improving energy utilization efficiency. In addition, the vacuum environment reduces the emission of pollutants and meets environmental protection requirements.

The control system can accurately control the carburizing process to ensure the repeatability and consistency of workpiece processing. At the same time, the workpiece has little deformation and a bright surface, and no subsequent machining is required.

It can be used as a stand-alone device or connected to a cold processing line. The equipment itself can be cyclical, suitable for small batch and multi-variety production, or continuous, suitable for large batch production.

It adopts cold wall vacuum technology, does not require ignition device, has no fire hazard, is simple to operate and easy to maintain.

| Model | Voltage (v) |

Power (kw) |

Temperature (°C) |

Working size (mm) |

|---|---|---|---|---|

| RJ3-25-6 | 380/3P | 25 | 650 | Ф400*500 |

| RJ3-35-6 | 380/3P | 35 | 650 | Ф500*650 |

| RJ3-55-6 | 380/3P | 55 | 650 | Ф700*900 |

| RJ3-75-6 | 380/3P | 75 | 650 | Ф950*1200 |

| RQ3-25-9 | 380/3P | 25 | 950 | Ф300*450 |

| RQ3-35-9 | 380/3P | 35 | 950 | Ф300*600 |

| RQ3-60-9 | 380/3P | 60 | 950 | Ф450*600 |

| RQ3-75-9 | 380/3P | 75 | 950 | Ф450*900 |

| RQ3-90-9 | 380/3P | 90 | 950 | Ф600*900 |

| RQ3-105-9 | 380/3P | 105 | 950 | Ф600*1200 |